Blurb not doing it for you?

If you've decided to produce your own book, here are a few tips for you to think about before you print. There are things for you to decide, which have to do with how it should be printed and how you want to have it bound. Here is a checklist for anyone who is interested, to help you get the best possible results:

Preparing Your Book for Self Publication

Prep of text:

- Single

sheets or signatures?

- Signatures

open flatter, book handles more flexibly.

- Margins- particularly

the left one if printing in single sheets –minimum ¾”.

Printing:

Here are a couple of places I recommend:

- Print

Zone, 191 Dundas St W., 416-204-9292.

- Mid

Town Reproductions, 384 Adelaide St

W., downstairs, 416-591-9010.

Selection

of paper:

- Weight- too thick and the book won’t open nicely. Too thin and you risk show-through.

GRAIN: parallel to the spine if

possible. The book's “flow” will be much more pleasant. Single sheets especially.

Binding:

- Single sheets are drilled and sewn.

- Signatures,

usually 12-16 pages, i.e 3 or 4

folds nested together, are sewn through the fold.

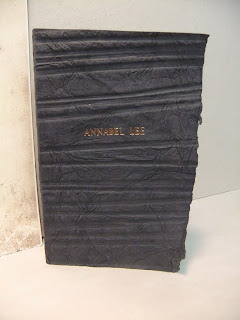

Case Binding:

- Hard cover, wrapped in

cloth, paper or leather or a combination.

- Cloth

or paper can be plain or printed. Some cloths will go through an inkjet machine.

- Paper

binding – in plain or print, hard or soft cover.

- Endpapers: white, coloured or printed. Found at art supply stores or The Paper Place.

- Leather can be purchased at Perfect Leather Goods, 555 King St. W.

Get

a sample before you buy in order to test stamping!

Stamping or debossing:

- Suitable for paper, cloth or leather.

- For

wordmarks, logos, any type face.

- Gold,

silver, pigment colours or “blind” i.e. no colour

- Die

art –Vector file, black and white, no half tones, produces a “MAG” magnesium

die, suitable

for hot stamping. I use KDS Graphics, they're at 140 Midwest Avenue, 416-752-0540

- When producing die art, keep in mind the weight of your lines. Little tiny feathery lines are difficult to stamp cleanly. Very broad lines are difficult to fill with foil. Keep lines medium weight.

Scheduling:

ALLOW ENOUGH TIME FOR THE PRINTING, and BINDING! -eg. time to

get the die made.

Submit

your material at least a week before you need it.